Services

1 - REQUIREMENTS

The CMMossini technical office is able to support all customer requests during design phase, choice of materials, processes, treatments, etc ...

2 - CO-DESIGN & DESIGN TO COST

Based on customer requirements, CMMossini supports every new project starting from the early stages of design and quotation, suggesting alternative solutions and specific tooling to reduce costs.

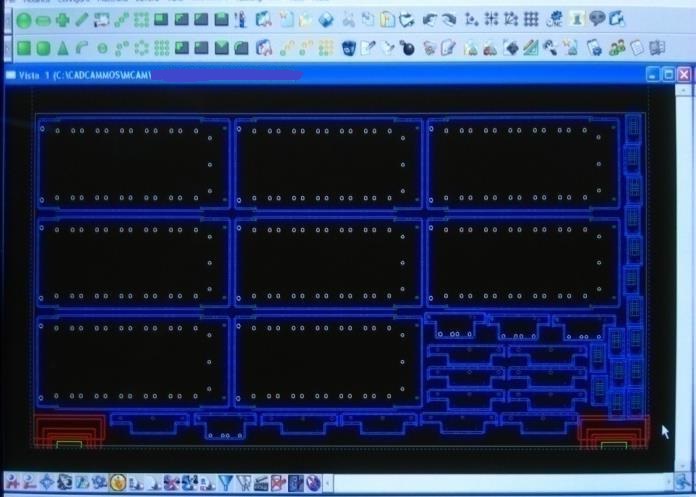

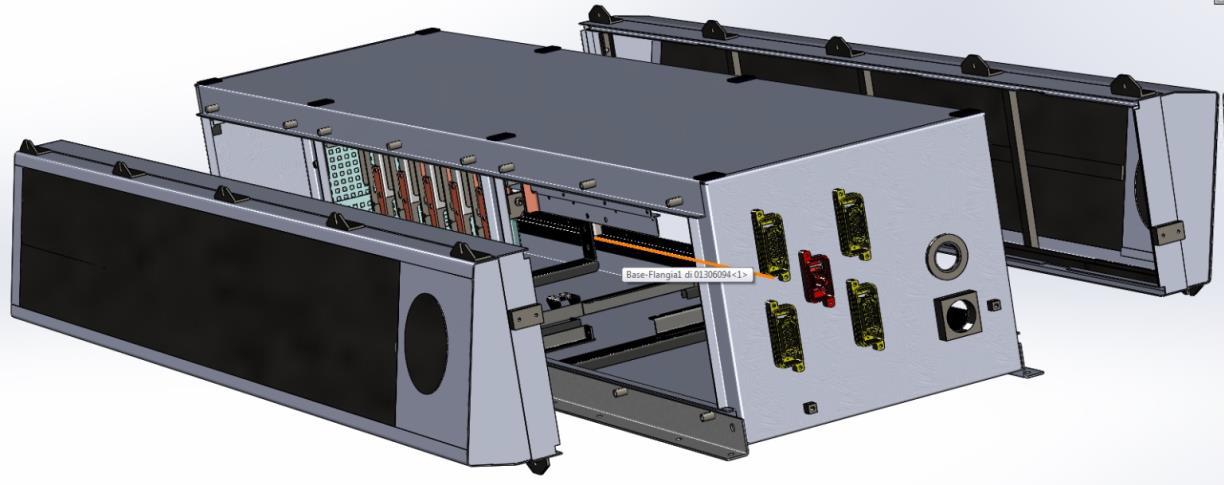

CAD AREA : The available software are able to manage the most common CAD file formats, export files as STP, IGES, DXF or directly native files from platforms CATIA, PROE, Solidworks.

CAM AREA : The IT systems involved in CAM programming of machines, are fully integrated with CNC numerical control machines, through a dedicated corporate network infrastructure.

3 - PROTOTYPE & NPI

CMMossini provides prototyping and NPI services, based on specific needs, and in compliance with the requested timing by the customer.

For a more responsive implementation of prototyping phase, CMMossini provides to customers the possibility to exchange data by sending the 3D model (single part or assembled ) and related information concerning, materials and treatments.

This methodology allows excellent results in terms of product quality and low realization lead times, and provides the opportunity to implement real time any changes and improvements, by updating the 3D file of the parts subject to review.

4 – QUALITY

The primary goal is the achievement of the standard required quality starting from prototyping and NPI phases, with measurements and dimensional reports, required for the prototype qualification and/or for the first piece of the production series.